Marchy

James Patton

Technical Fields

This product involves the technical fields of Digital Design, Digital Fabrication, and Additive Manufacturing.

Background Information

The idea for Marchy comes from personal experience as a trumpet player and experiencing severe headaches as a result of playing the instrument. These headaches became significantly amplified during the transition from a seated posture during concert band to a standing and head-high posture during marching band. The threshold between having a splitting headache and not, often came from a slight change in head and neck angle, but was noticeable from the audience’s perspective.

Prior Art (Research)

Bent Mouthpieces

Thompson, R. S. (2001, March 6). Angled mouthpiece for wind instrument. https://patents.google.com/patent/US6198032B1/en

(expired 03/03/2020)

Often performed by music shops, and apparently patented by Robert Shawn Thompson from 2000-2020, mouthpiece bending is a relatively common practice for a similar solution of changing the angle between the mouthpiece and the horn.

This technique is typically performed without precision, often ruining the trueness of the mouthpiece shank, which can cause damage to the instrument. Bending mouthpieces can also introduce a sharp pinch point on the inside of the mouthpiece, further reducing airflow and causing more pressure for the player.

Stomvi “Flex Coupler”

Stomvi. (n.d.). Flex Coupler. Stomvi-USA. https://stomvi-usa.com/product/flex-coupler/

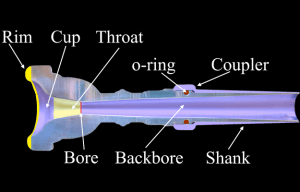

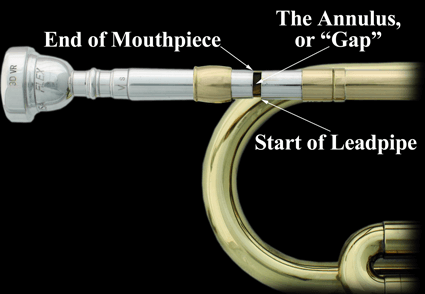

Stomvi’s Flex Coupler is a small drop-in device that goes between the mouthpiece shank and receiver of the instrument. This device, while titled “Flex”, is not actually flexible, but functions as a shim to adjust the annulus, or gap between the end of the mouthpiece, and the internal start oft the leadpipe taper.

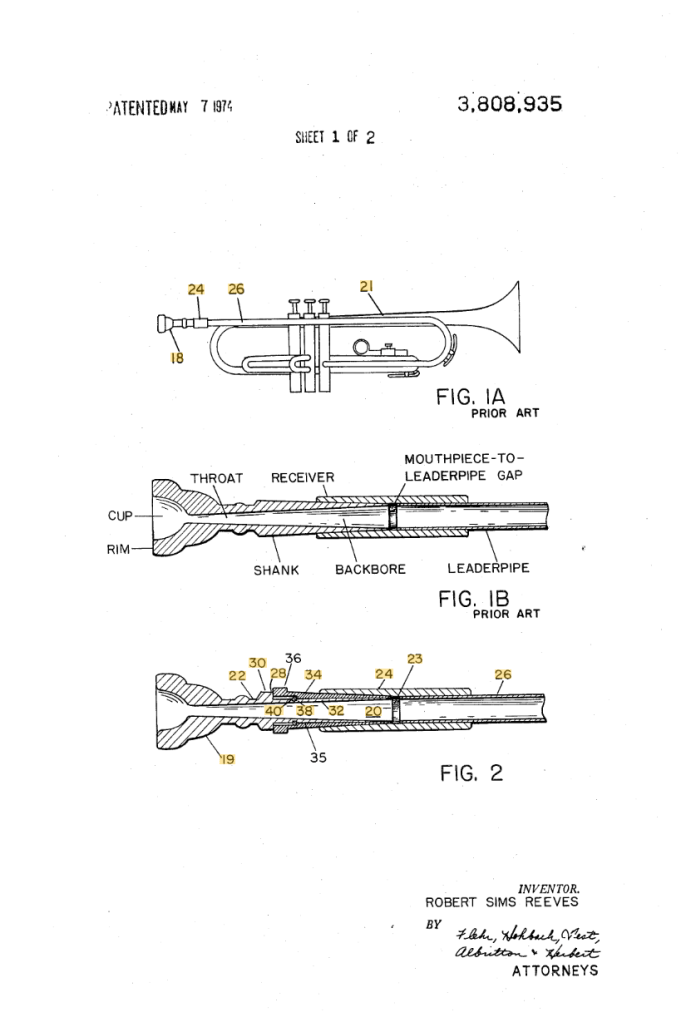

Stomvi does not hold an active patent on this item, but furthermore utilizes a sleeve design denoted by Robert Sims Reeves in his now-expired patent US3808935A

https://patents.google.com/patent/US3808935A/en

Project Description

The full deliverable of this project is a compliant joint that fits between the mouthpiece and shank receiver of bell-front brasswind instruments. This is intended for marching brasswind performers, but is applicable across the entire industry of performing brasswind musicians. The compliant mechanism can provide ease to any brasswind performer whose head pressure is dictated by posture and head angle. By changing the straight line between mouthpiece and instrument, the performer can have a head/neck angle different from that of their instrument, allowing for comfort and ease while maintaining visual accuracy as required by the performing ensemble.

Innovation Claim

The innovation of Marchy allows for an adaptive angle between the instrument and mouthpiece. While existing solutions can introduce a fixed angle between the instrument and mouthpiece, Marchy allows for the angle to change as needed, all without the need for expensive and potentially damaging modifications to the instrument and mouthpiece.

Usage Scenario

A compliant relief mechanism in between a wind instrument and its mouthpiece is not simply limited to marching brass. It is commonplace in jazz ensembles and big bands that wind performers maintain a somewhat non-neutral performing posture to project sound or maintain a consistent visual. Saxophonists often lean forward towards their instruments to reduce various strains and take weights off of the performer, but this often comes with a bend at the neck. A compliant joint at the mouthpiece of the instrument can enable a performer to take more stress off of their body and arms, while also maintaining a straight and neutral neck, decreasing any potential stresses that come from the respiratory aspect of playing the instrument. This type of joint could likely be optimized and fitted to other types of wind instruments, such as bass clarinet or bassoon, where the posture is often determined by the tuning/height of the instrument.

Evaluation Criteria

The following yes/no questions will identify the successful completion of the project.

- Has Marchy been made compatible with all conventional marching brass instruments?

- Has the prototype been demonstrated to survive 10,000 or more bends?

- Have the proper patent documents been filed with USPTO to secure Patent Pending status?

- Has Marchy been demonstrated by other players, and been critiqued as such?

- Can a novice or intermediate player continue to play their instrument with Marchy?

- Is a player using Marchy unnoticeable from the pressbox?

- Does Marchy maintain the tone quality of the instrument on which it is installed?

Goals and Tasks Associated with the Project

- Acquire standard brasswind instruments used in 21st century American marching bands ✅

- Trumpet

- Cornet

- Mellophone

- Trombone

- Baritone/Euphonium

- Contrabass/Tuba

- File provisional patent documents and receive Patent Pending certification for USPTO

- Develop a functional prototype to fit every standard brasswind instrument and its mouthpiece ✅

- Sketch parts based off of mouthpiece dimensions ✅

- Print new prototypes ✅

- Ensure fitment and 10+ degrees of compliance for each instrument

- Develop a testing system to stress-test the prototype for longevity

- Simple cam+motor system to deflect part 10+ degrees

- Monitoring camera to record longevity

- Torture test each part to a minimum 10,000 bends

- Record a playing demonstration on all instruments to demonstrate functionality: videos with and without Marchy

- Ensure each instrument+Marchy configuration maintains most, if not all of the tone quality of the player

- Check for Marchy-induced intonation issues in recordings

- Send prototypes to beta testers and industry professionals (Fall ‘25) (postponed to ’26)

- Send to schools, marching programs

- Check visibility (can it be seen from a distance?)

- Log feedback

- Revise prototypes based on feedback

- Produce final products for each instrument

- Produce individual, bundle, and ensemble pricing scales

- Finalize patent documents

- Take to NSBA or NMEA conferences (2026)

Description of Design Prototype

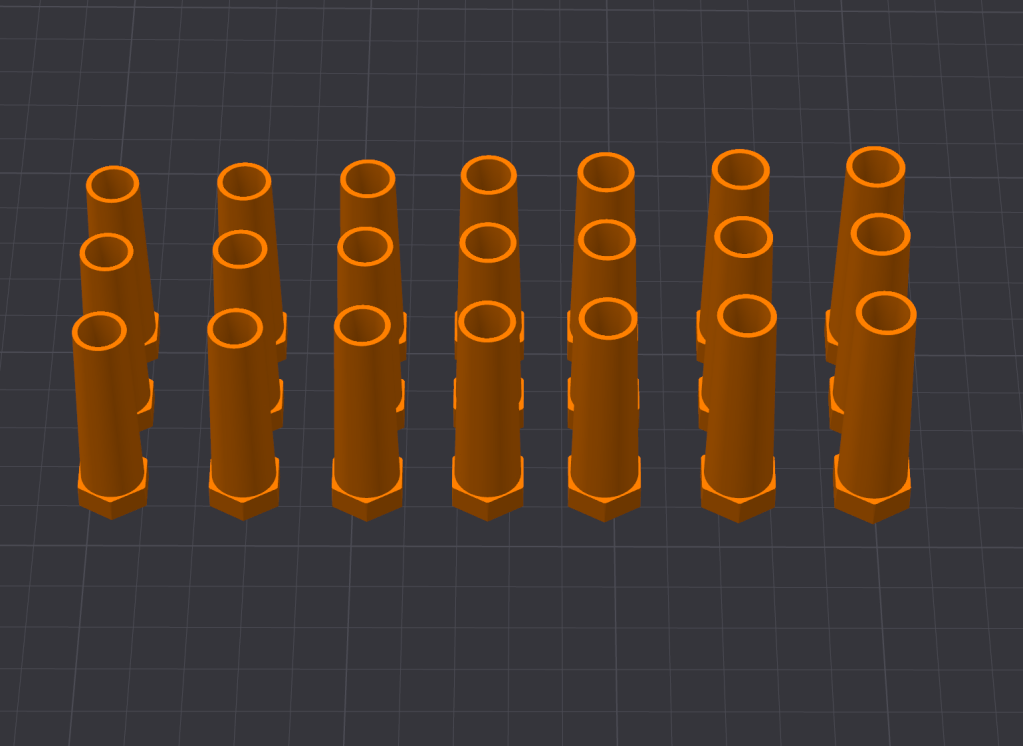

Prototype is designed in Autodesk Inventor to be manufactured using Fused Deposition Modeling technology. Materials to manufacture include various hardnesses of Thermoplastic Polyurethane (TPU) and potentially strips of spring steel. Prototype form is a hollow taper to match the geometries of the inner taper of the instrument receiver, and the outer taper of the mouthpiece. Taper rate is standard Morse.

Prototype usage and implementation involves one extra step to brass instrument assembly from case to playing. Normal instrument assembly is as follows:

- Remove instrument from case

- Remove mouthpiece from protective enclosure within case

- Slide mouthpiece shank into leadpipe receiver

- Press and twist to snugly attach the taper of the mouthpiece to the receiver

- Verify instrument function:

- Valves/rotors

- Tuning slides

- Water keys

- Play test

- Tuning

The only addition will involve placing Marchy on the shank of the mouthpiece, and inserting the assembly into the receiver of the horn, in between steps 2 and 3.

The instrument will need to be tuned in (sharpened) slightly to accommodate for the increase in tubing length.

The final result will consist of a brass instrument with a compliant joint between its mouthpiece and receiver.

Tolerance and Material Testing

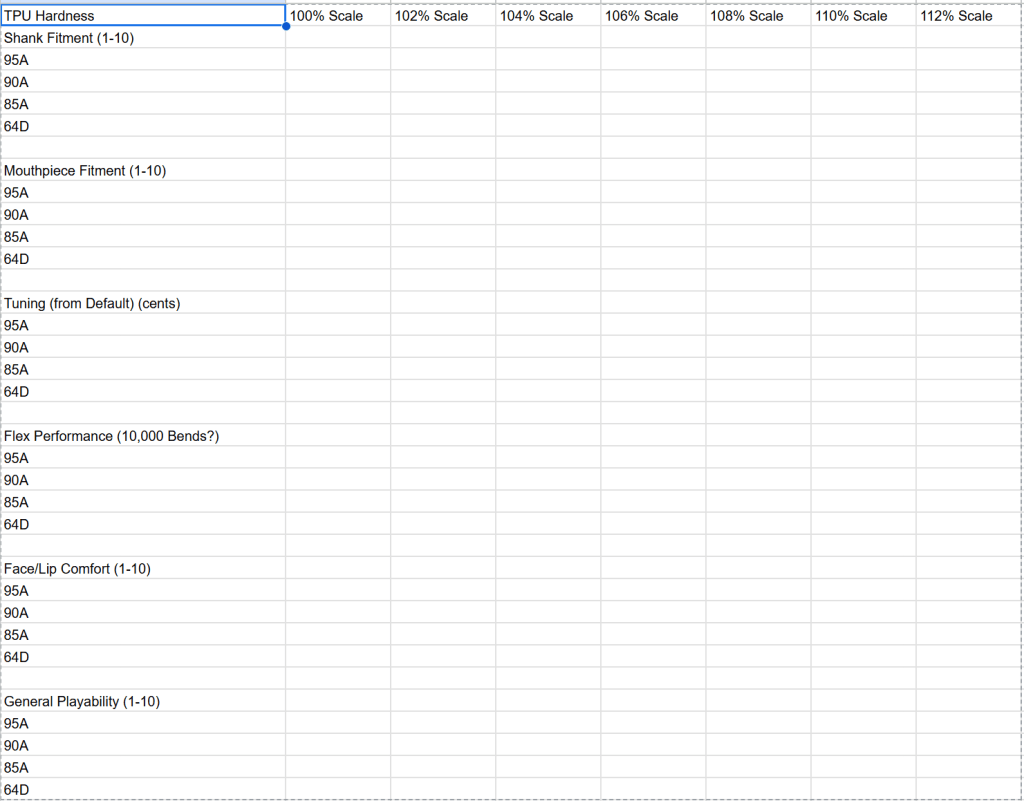

As of November 2025, a functional and working prototype has been established for all brass instruments, but now the optimal tolerances and materials must be tested. Four different hardnesses of Thermoplastic Polyurethane (TPU) have been selected for this stage: 95A, 90A, 85A, and 64D. Performance of each of these will be graded as such:

Three samples of each size and material will be printed to establish a baseline, tested, and a conclusive tolerance and material combination will be chosen to construct the final product. This will be done for each instrument group.

Current Production

As of January 2026, production of the testing series (trumpet) has already begun. This set of prototypes, from 100% scale to 112% scale will be produced to best determine which fits the majority of trumpets and mouthpieces.

Low brass instruments, such as baritone and tuba , have less tolerance demand in the mouthpiece shank, so less iterations will be produced.

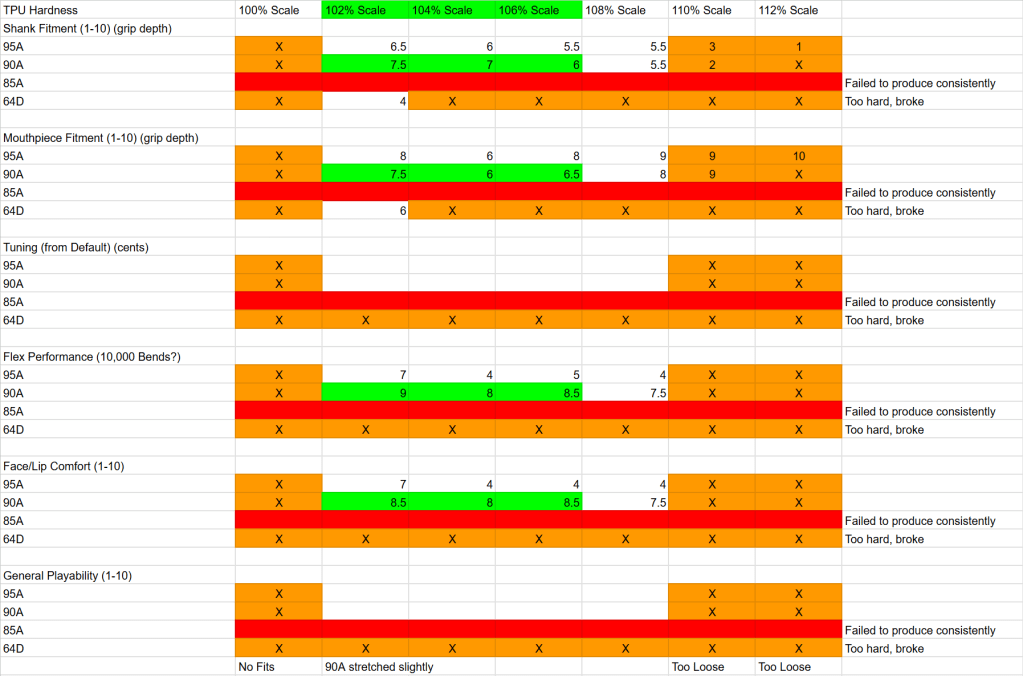

Half of the prototypes have been completed for fitment and basic mobility testing. Blue is 95A, white is 64D

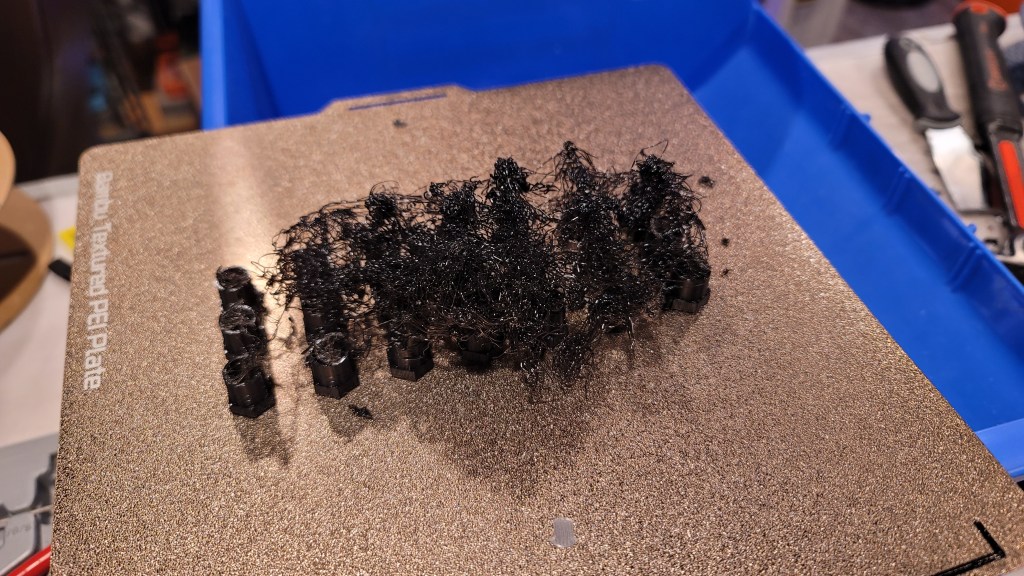

As of January 25, all prototypes have been created for initial testing. Due to 3 prints worth of spaghetti, the 85A TPU has been disqualified from the initial testing phase, as it is too unreliable to print given current equipment. It also feels way too soft, and will likely need an entire redesign to work.

Depending on prototype fitment success, there is also a multi-material design in the works.

Current chart progress is as such (Feb 1)

Testing shows that the optimal size is between 102% and 106% scaling of the design, and the optimal material is 90A TPU. This gives a good flex and grip on both sides without sagging horribly.

Play and torture testing will be performed on the 90A TPU parts scaled from 102-106% this month

Three prototypes broke during fitment testing alone, with many other 64D prototypes cracking in the hand when squeezed. More optimization could be done for the 64D and 95A TPU printing, but they do not flex nearly enough to justify the labor. 90A TPU will be optimized, and variable thicknesses may be produced depending on results. Layer adhesion with TPU is typically not an issue, but settings can be tweaked to increase strength. Torture testing will help reel in these ideal settings.